-

Ceramic Milling Ball Zirconia Grinding Beads

The surface of the Ceramic Milling Ball Zirconia Grinding Beads is smooth, the strength is greatly improved, and the damage rate is greatly reduced. The damage to the equipment is reduced, which effectively extends the service life of the equipment. It is mainly used for grinding and dispersing ceramic materials, food, cosmetics, paint, coatings, pigments, and inks.

-

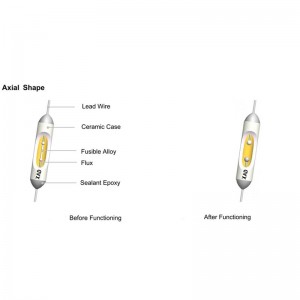

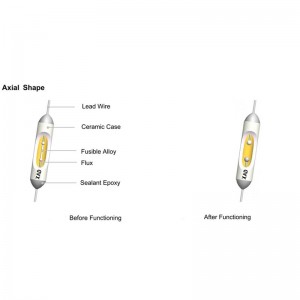

Alloy thermal cutoff

Alloy thermal cutoff is a one time, non returnable device.It is widely used in over-temperature protection of electrical equipment. The utility model is mainly composed of a fusible alloy with low melting point, a flux, a plastic or ceramic shell, a sealing resin and a lead wire. Under normal operating conditions, the flammable alloy is connected to both leads, and the fusible alloy melts when the alloy thermal cutoff feels abnormal heat and reaches a predetermined fuse temperature, and in the role of the fuse under the fast contraction to the two ends of the lead, thus breaking the circuit.

Alloy thermal cutoff are axial type and radial type, rated action temperature: 76-230 °C, rated current: 1-200A, safety certification including: Rohs CCC,REACH and other environmental protection requirements

-

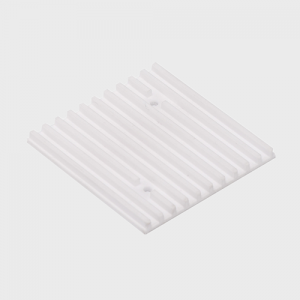

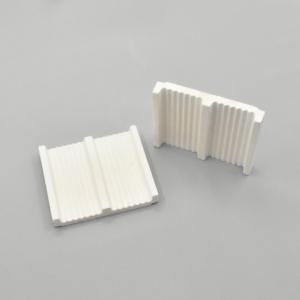

Ceramic Heat Sink

Ceramic heat sink is mainly composed of a heat dissipation layer and a heat conduction layer, the heat dissipation layer is the use of liquid phase chemical change principle to latex slurry uneven dispersion, the formation of ceramic powder thin structure, and combined with sub-micron powder, and then fired into hollow crystal cavity structure heat dissipation layer, the porosity of the micro cavity structure of the heat dissipation layer between 5% and 40%, The particle size of the powder is between 90 nm and 300 nm. The contact surface with the heat source has a thermal conductivity layer, which absorbs and conducts the heat source. Through the high surface area of the porous structure of the heat dissipation layer, the heat dissipation capacity is improved by using the air as the heat dissipation medium.

-

Alumina Ceramic Ring

The ceramic parts at room temperature is an insulator, because of high resistivity so can be used in insulating equipment, with high melting point, high boiling point characteristics, make up for the metal materials at high temperature easy oxidation, easy corrosion of weakness. And because the product material has no magnetic, it does not absorb dust, the surface is not easy to fall off.

-

Granulation powder

As an important molding method in advanced ceramic production, compression molding has been more and more widely used. Because of the more and more detailed requirements for the raw materials, it is necessary to process the material into particles which can fill the model evenly, improve the forming density of the green body and ensure the sintering density after the production in order to improve the fluidity of porcelain material, improve sintering performance, reduce sintering temperature. Therefore, the Granulation powder is particularly important to produce ceramics.

-

Capacitive ceramic pressure element

Capacitive ceramic pressure element (CCP) is a product dedicated to the automotive market. Precision molding process is adopted to normalize the production of sensor substrates. The automatic rotary tunnel furnace improves the sintering stability to produce better sensor substrates. Our substrate has high processing accuracy and good material stability, which can improve the quality of the sensor.

-

Ceramic Water Valve Plate Disc

Al2O3 Ceramic Water Valve Plate/Disc has the characteristics of corrosion resistance, high temperature resistance, wear resistance, Good parallelism accuracy, high hardness, etc.

-

Ceramic aluminum titanate sprue sleeve bushing

Ceramic aluminum titanate sprue sleeve bushing is the key part of the low-pressure aluminum casting machine.

Ceramic aluminum titanate sprue sleeve bushing is a critical part of low-pressure casting machines. Molten aluminum is transported by pressure from holding furnace via riser tube into a mold every 3-5 minutes. aluminum titanate becomes the ideal material of riser tubes due to its low thermal expansion coefficient, good thermal shock resistance and no wetting by molten metals.

-

Self-lubricating Ceramic Shaft and Shaft seal

Self-lubricating Ceramic Shaft / Shaft seal have improved the material properties on the basis of maintaining the original high strength, acid and alkali resistance, and friction resistance of alumina products. The biggest feature is the reduction of the coefficient of friction. The shafts and shaft seals using this material show obvious advantages. For example: longer life, lower noise, better stability, and better protection of the motor.

The micro-textured self-lubricating ceramic material improves the comprehensive mechanical properties of the Al2O3 ceramic material. The fracture toughness and flexural strength of the brown self-lubricating ceramic shaft are 7.43MPa·m1/2 and 504.8MPa, respectively, which are about 0.4% and 12.3% higher than the ordinary alumina ceramic shaft, the maximum friction coefficient is reduced by about 33.3% and the minimum friction coefficient is reduced by about 18.2%.

-

Aluminum oxide Ceramic shaft / Shaft seal

We adopt precision molding process large-scale production of alumina ceramic shaft, ceramic bearing. Alumina ceramic shaft, ceramic bearing with heat and cold resistance, small force elasticity, pressure resistance, light weight, small friction coefficient and so on some advantages, widely used in high number motor.

-

Alumina Hollow Bulb Brick / Alumina Bubble Brick

Alumina hollow bulb brick/ Alumina bubble brick is a light alumina product made of industrial alumina by melt-blown method. The lightweight refractory insulation bricks made from the hollow bulb can be used as linings in high temperature furnaces in direct contact with flames.

-

Sintering Fixture

Our push plates and crucibles have the advantages of high alumina content, low impurity content, high temperature resistance, good thermal shock stability and low expansion coefficient.