Cov nyhuv ntawmmicroporous ceramic atomizing corentawm hluav taws xob smog

1. Porosity vs. lub zog

Thawj qhov tsis sib xws ntawm ceramics: qhov txo qis ntawm lub zog yuav ua rau cov ceramics poob cov hmoov, thaum kawg ntawm lub caij nplooj zeeg, lub rooj sib txoos ua rau muaj kev tawg, ua rau txo cov qoob loo.

2. Pore loj vs. roj conductivity

Qhov pore loj ntawmmicroporous ceramicsyog qhov tsis sib xws hauv microstructure thiab tsis muaj geometry tsis tu ncua.Qhov pore loj los yog me me.Lub aperture ntawm microporous ceramics feem ntau yog hais txog kev faib tawm ib ntus, nyob rau hauv qhov nruam ntws channel, qhov tsawg kawg nkaus aperture rau tus nqi ntawm cov roj ua lub luag haujlwm txiav txim siab, tus nqi ntawm cov roj yog proportional rau lub square ntawm lub aperture, qhov loj dua qhov aperture, ceev cov roj.

3. Aperture vs. kev ntxhib los mos

Ntxiv rau qhov cuam tshuam rau cov roj conduction tus nqi, aperture yog lwm qhov taw qhia tseem ceeb yog qhov saj.Thaum atomizing, yog tias cov roj pa luam yeeb yog cov khoom loj dua atomized, cov dej ntws tsim yog coarse, thiab cov tee dej tom qab condensation loj dua, uas muaj qhov muaj zog thiab zoo siab saj.Qhov me me ntawm lub qhov, qhov zoo dua cov dej ntws los ntawm cov roj atomization, qhov zoo dua cov aerosol hais tsim, qhov zoo dua cov nyhuv dispersion, zoo ib yam, ilv saj.Yog li ntawd, qhov me me ntawm cov roj qhia aperture, qhov zoo dua.

Kev tsom xam ntawm cov ntsiab lus mob ntawmmicroporous ceramic atomizing core

Cov khoom siv roj conduction thiab lub zog ntawm ceramics tsis tuaj yeem suav nrog, yog li xav tau aperture loj kom tau txais cov peev txheej roj txaus.Loj aperture yuav ua rau lub aperture ntawm ceramic txo;Zoo saj ntawm ceramic atomizing core yuav tsum me me txaus aperture;Ceramic zog, roj conduction, saj yuav tsum tau rau aperture yog raws nraim opposite.Ceramics nyob rau hauv peb qhov kev ua tau zoo tsis tuaj yeem ua rau ob qho tib si, nws yog qhov tsis sib xws.Tab sis cov tub ntxhais ntawm ceramic atomization core, nrog rau kev sib tw tseem ceeb ntawm e-luam yeeb yog qhov saj, uas yog qhov kev ua tau zoo uas yuav tsum tau lav ua ntej.Yog li ntawd, qhov pore loj me me txaus los muab cov roj txaus.

1. Fine pore loj thiab siab porosity:

Nano ceramic khoom npaj technology, tswj cov particle loj thiab concentration ntawm ceramic hmoov, tau zoo pore qauv thiab concentrated pore loj faib, zam lub zog poob los ntawm loj pores.Optimize lub dispersion uniformity ntawm ceramic hmoov, nce lub pore-ua koob tshuaj, thiab ua tau siab porosity

2. Lub teeb ntawmmicroporous ceramics:

Hloov cov khoom siv mis, txhim kho lub zog ntawm cov khoom siv microporous ceramic, raug tsim thiab tswj qhov kub ntawm sintering, kom tau txais cov qib zoo sintering, kom ua tiav qhov sib npaug ntawm porosity thiab lub zog.Precise industrial design yuav ua tiav qhov sib npaug ntawm lub zog, porosity thiab aperture, kom ua tiav cov roj zoo tagnrho thiab cov nyhuv saj.

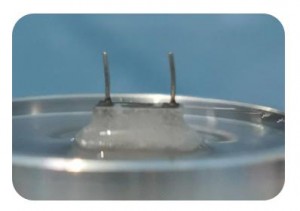

3. Lwm qhov mob ntawm cov tub ntxhais ceramic yog evaporation ntawm nicotine thiab essence hauv cov roj luam yeeb.Nws xav tau qhov kub thiab txias ib puag ncig, thiab qhov kub thiab txias tsis sib xws.Txhawm rau ua raws li qhov kawg saj, cov cua sov hlau ua haujlwm yog xav tau rau kev ua haujlwm zoo thiab kev kho kom zoo, yog li tam sim no txoj kev loj hlob ntawm microporous ceramic atomization core yog ua ib qho customized metallization ntawm ceramic substrate.Muaj ntau txoj hauv kev los metallize ceramic nto, thiab ib qho ntawm cov thev naus laus zis niaj hnub no siv hauv e-luam yeeb yog tuab zaj duab xis luam ntawv, zoo ib yam li PCB txhuam txhuam.Cov txheej txheem no tsis yog tsuas yog siv rau ntawm qhov chaw tiaj tus, tab sis kuj yog ntawm 3D nto.

Post lub sij hawm: Lub Xya hli ntuj-19-2022